Made in Bangladesh Pop-culture Collectibles- the story of Pixee and Light Up

Rakib and Samiya started Pixee and Light Up, meeting a niche local demand for fan merchandise and making it accessible for all.

Made in Bangladesh Pop-culture Collectibles- the story of Pixee and Light Up

Rakib and Samiya started Pixee and Light Up, meeting a niche local demand for fan merchandise and making it accessible for all.

Nerd culture in Bangladesh appeals to a vastly different demographic from the common Western textbook, figurine-collecting stereotype. Wearing this hoodie from a favourite series or curating a collection of memorabilia from that popular franchise earns the ‘trendy’ badge in a friend group.

The contrast of our geeks with that of Western countries can partly be attributed to the lavishness of owning merchandise of foreign media.

Only a few pop-culture merch stores have captured the entirety of this rising market in Bangladesh, and their entire inventory is imported from the US, Japan, or China – making the merch a sort of costly status symbol for teens.

How it all started

There is still one pain point for the geeks: scarcity or unavailability of collectibles from their niche area of interest. The stores’ inventories cannot catch up with the demand of ever-growing fandoms. Such was the case of Rakib Hasan as well, who searched every local store for a figurine of Minecraft’s Enderman. It was available on AliExpress, like everything else. However, a delivery window of 30-50 days and a shipping cost beyond the budget did not help his cause.

“After researching for a bit it hit me,” he said, “that if a 3D-rendered model can be turned into a low-poly model, a papercraft can be made.” Repurposing an old, high-quality printer (plotter) from a previous business, he promptly executed as he intended, gathering praise from friends and family. Thus, Pixee was born with co-founders Rakib Hasan and Samiya Alom.

A novelty in paper crafting

Pixee’s range of products includes character figurines, 3D posters, masks, castles, and even dioramas of famous locations in pop culture. All of it is crafted using one material – cardstock. It is essentially a thicker variant of paper – 270 GSM to be exact, whereas the paper we use daily is usually 60 GSM.

Cardstock paper-crafting was popular in the 90s since 3D printing was not popularised yet then. It is still reasonably popular abroad and is sold as DIY kits for models. Rakib wanted to implement that here as well, adding a detailed instruction manual with the parts. But he realised that it is not a product-market fit here as people expect ready-made products only.

The creative process

Originality is at the heart of Pixee. Every product is 3D modelled from scratch at their own workstation. The 3D model is then generated as a papercraft template which is printed and cut with the plotter.

The parts are then delivered to their team of 6-7 skilled employees who work from their own homes following thorough instructions. Every week, the co-founders collect the assembled products from them and put a final coating before delivering the finished product.

The challenges resolved

Making ready-made products came with its own set of challenges. The cardstock is not available here, thus has to be imported from China. A lot of trial and error went into choosing the perfect glue to make a stable product.

An extra layer of coating goes on the final product to make it dust-proof and splash-proof, making it low-maintenance for the collector.

The next hurdle was of untampered packaging. The products are fragile, but the delivery service does not provide the fragile handling feature in the area of their Narayanganj workstation.

After going through another set of trials and errors, they settled on a combination of paper strips, styrofoam cushions, and bubble wrap.

Popular among the customers

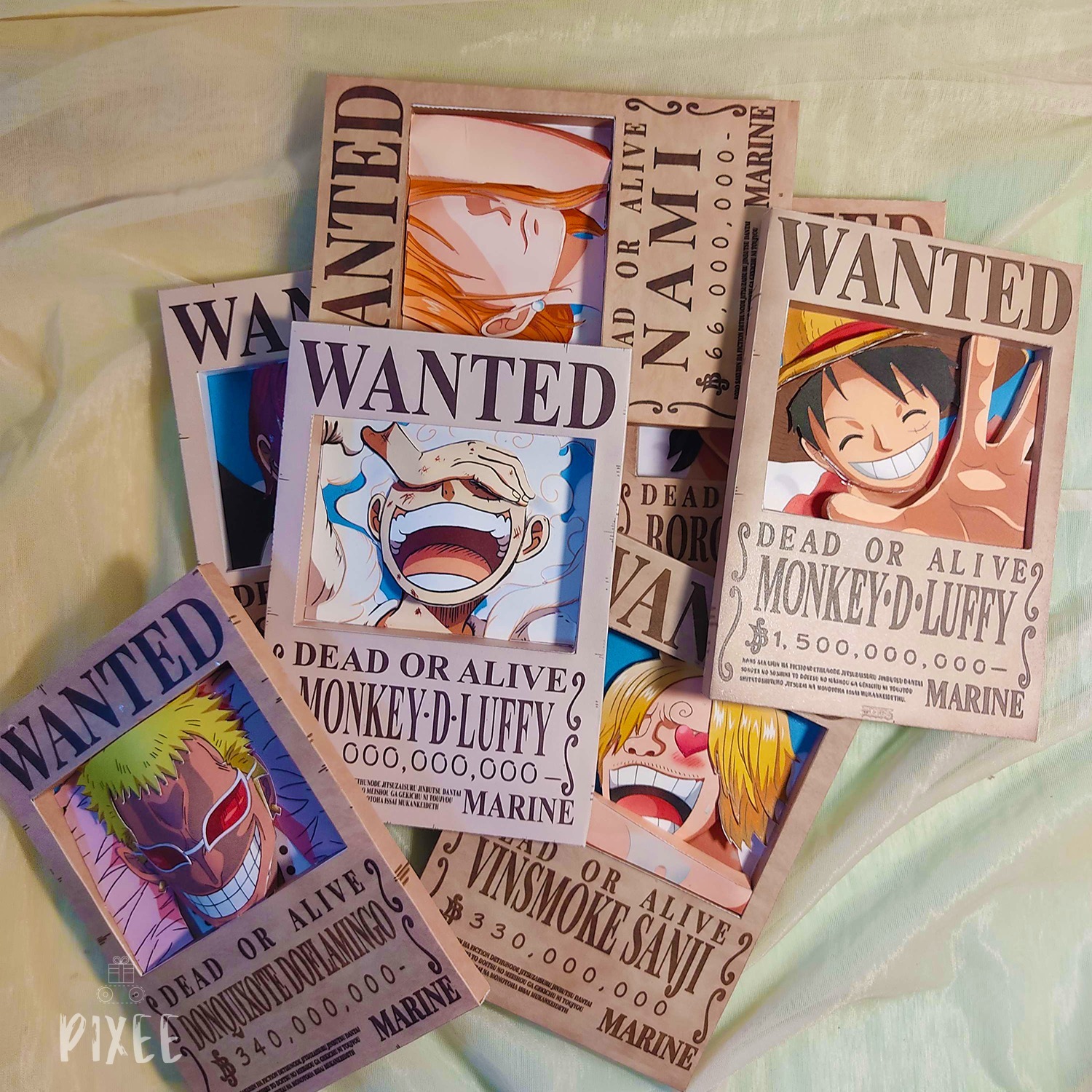

Co-founder Samiya Alom mentioned that some of their best-sellers are from the anime category. The action figures within the range of Tk360-430 are popular choices among clients. They recently launched their own line of Funko Pops, paired with a recreated version of the familiar Funko box, and it was an instant hit.

What makes Pixee special is that it provides customisation services so that no niche pop-culture interest gets left behind. The Funko box itself was at first a custom order. When Pixee made and posted a custom-ordered Funko box of Valorant’s Omen, more orders started flooding in, leading to their decision to launch the Funko Pop lineup.

Expansion to Light Up

Lightbox is one of the latest aesthetic collectibles in pop culture. Doubling as a dim bedside lamp, this ‘useful’ collectible offers two vastly different yet equally mesmerising views of the same scene/character closeup when the light in the background is switched on or off.

The co-founders of Pixee wasted no time hopping onto this trend and introduced their own line of cardstock-based lightboxes.

Interestingly, they decided to keep only this category as a separate entity with separate social media handles. Samiya explained, “We were looking for ways of product improvement in Pixee.

When we stumbled upon lightboxes, we found that this product is sturdy, as opposed to Pixee’s. Hence, the transportation method is different. And this is a huge genre that, when served with Pixee, can get people confused. So, we shifted it to a new page to protect the authenticity of Pixee while letting Light Up thrive on its own.”

Diving deep into the layers of lightbox

What makes these lightboxes especially pleasing to look at is the brilliant chiaroscuro and silhouette across the different layers. The fascinating assembly process begs the question of the design process.

Samiya shared, “At first we need a still image of what we want to make a lightbox out of. Every still image has different types of colours, layers, and objects. We separate all of them into different layers on the computer. Then we print and cut all the different coloured layers one by one, assemble them and install a light. This is how the 3D effect is created.”

Rakib and Samiya have a shared vision of distributing Pixee products nationwide, making them accessible to all. Since these products are fragile, exporting to foreign countries is still an issue.

Moreover, implementing this vision with the soaring pressure of academics is also hard on them. Being an HSC candidate, Samiya has to take time off the business occasionally.

The decision to hire employees stemmed from their incapacity to keep up with the demand amidst other commitments. Yet, they dream big. Since Light Up products are sturdier, they plan on creating the biggest collection of lightboxes and putting each product up for export.